Unveiling the Secrets of Steel Rope Manufacturing: A Step-by-Step Guide

Introduction:

Delving into the world of steel rope manufacturing may seem like a daunting task at first glance, but a closer inspection reveals a stunning symphony of precision, process, and perseverance. Its methodical intricacy endears much respect, complex yet captivating. With the following step-by-step guide, we aim to illuminate the subtle intricacies and zealous precision required to manufacture steel ropes.

Section 1: The Material: Steel Wires

Crafting a strong steel rope starts with ensuring strong raw materials. Steel wires of varying diameters deserve attention for their distinct properties, including flexibility, strength, and resistance to wear, fatigue, and corrosion. Their selection varies depending on the end purpose of the steel rope.

Section 2: The Twisting Process

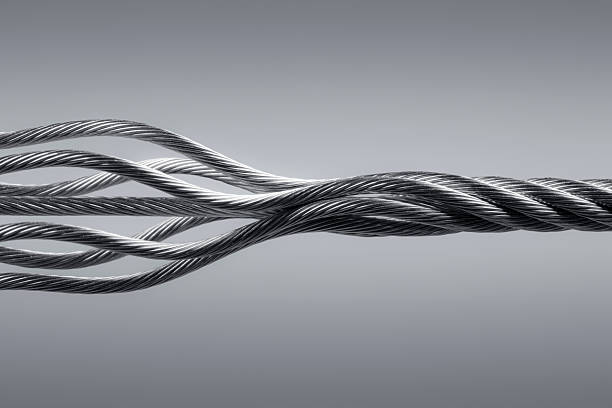

A significant step in steel rope production is the twisting of individual steel wires into strands. A precise and uniform twisting process is vital to ensure optimal strength and flexibility. This process can create strands of different layouts and forms, such as alternate lay strands and equal lay strands, each carrying its own unique capabilities.

Section 3: Closing – The Art of Forming the Rope

A vital part in the process is 'closing'—intertwining strands around a core to transform it into a fully realized wire rope. The method employed, whether it's creating a Lang lay rope or regular lay rope, determines the rope's characteristics and application suitability. This stage not only validates the rope's power but also features the artistry inherent in the process.

Section 4: Testing and Quality Control

After the rope has been manufactured, it undergoes rigorous testing for parameters, such as tensile strength, flexibility, and resistance to fatigue and wear. These quality assurance tests verify the steel rope's adherence to international standards and customer requirements.

Section 5: The Applications: Where Steel Rope Excels

The applications of steel rope are numerous—be it in construction, elevators, or mining industries. Each type of rope constructed through specific processes excels in certain application due to its inherent strength, flexibility, and resistance.

Conclusion: The End Product – A Testament to Precision and Strength

Each steel rope that rolls off the production line is a testament to the meticulous precision and unyielding strength that is the hallmark of this industry. With every twist, turn, and tension test, the passion and commitment behind its creation become undeniably evident.

We hope this step by step guide offers a comfortable read; understanding the steel rope manufacturing process sheds light on the awe-inspiring intersection of raw materials, meticulous construction, and rigorous testing.