Discover the Cutting-Edge Sustainability Practices of Steel Rope Production

Implementing Eco-Friendly Raw Materials

In the quest for sustainability, the selection of raw materials is a crucial first step. The steel industry has been historically known for its heavy environmental footprint. However, recent advancements have paved the way for more sustainable practices, starting with the raw materials used in steel rope production.

Sourcing Green Steel for Rope Production

The concept of 'green steel' refers to steel produced using methods that emit less carbon and are generally more environmentally friendly. This includes using renewable energy sources and reducing the use of carbon-intensive coking coal. Companies have started sourcing green steel for rope production, acknowledging its reduced impact on the environment. They are partnering with suppliers employing innovative smelting technologies that use electricity from renewable sources, thus cutting down carbon emissions significantly.

Reducing Reliance on Non-Renewable Resources

Another aspect of implementing eco-friendly raw materials is reducing the reliance on non-renewable resources. This means exploring alternatives like biologically derived materials or enhanced recycling programs to minimize the need for virgin materials. By doing so, not only does it decrease environmental degradation, but it also encourages the development of a circular economy where materials are reused and repurposed, rather than disposed of.

Innovations in Recycled Material Usage

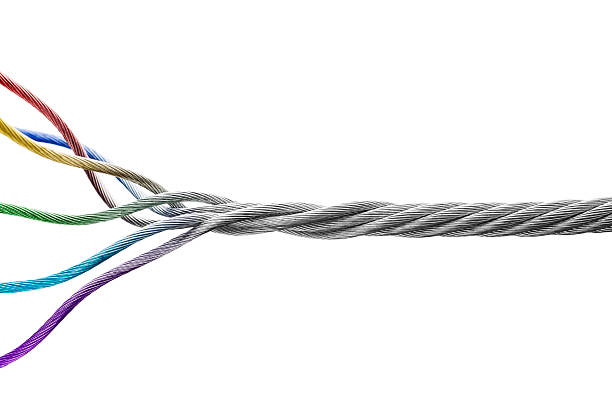

Innovations in recycling have a pivotal role in transforming the steel rope industry. Technological advancements have made it possible to increase the content of recycled materials in steel rope without compromising its strength or durability. This is indeed a game-changer as it leads to a significant reduction in waste and conserves natural resources by giving scrap steel new life.

Energy Efficiency in Manufacturing

With a clear understanding of the importance of raw materials, we now turn to energy efficiency in manufacturing. The energy consumed during production contributes greatly to the overall environmental impact of steel ropes. Thus, minimizing energy usage is key to enhancing their sustainability.

Adopting Renewable Energy Sources

One of the most effective ways to increase energy efficiency is by switching to renewable energy sources. Solar, wind, and hydroelectric power can provide the necessary energy to run operations while drastically reducing greenhouse gas emissions. Many manufacturers are committing to this transition, investing in onsite renewable energy facilities or purchasing green energy from utility providers.

Streamlining the Production Process

Beyond just the type of energy, how energy is used in the manufacturing process also matters. Streamlining operations to reduce energy consumption can lead to substantial improvements in efficiency. This involves optimizing machinery, reducing heat loss, improving insulation, and implementing smart sensors and controls to adjust energy use in real-time.

Energy Recovery and Reuse Strategies

An often overlooked but vital strategy is recovering energy from the production process itself. For example, the heat generated in steelmaking can be captured and reused, reducing the need for additional heating and saving energy. Manufacturers are developing systems to reclaim this otherwise wasted energy, integrating it back into the production cycle or using it to power other facilities.

Waste Reduction and Product Lifecycle Management

Moving beyond the production phase, managing waste and the lifecycle of steel ropes is integral to sustainable practices. This encompasses strategies aimed at reducing waste generation and considering the product's end of life during the design phase.

Zero-Waste Initiatives in Steel Rope Production

Zero-waste initiatives are ambitious but increasingly achievable goals set by companies to eliminate waste. This involves redesigning processes and products to prevent waste creation and finding uses for by-products. For instance, scale and dust generated during manufacturing can be processed and utilized in other industries such as cement making.

Extending Product Life through Innovative Designs

Design innovation plays a critical role in extending the lifespan of steel ropes. By enhancing the design, ropes can become more durable, resistant to wear, and easier to maintain. This not only improves the product's performance but also reduces the frequency of replacement, thereby decreasing the demand for new materials.

Recycling and Upcycling Post-Consumer Steel Rope

At the product's end of life, recycling and upcycling become important. Steel is inherently recyclable, and post-consumer steel ropes can be melted down and remade into new products, closing the loop. Upcycling, which involves repurposing waste into products of higher value, is also gaining traction. Creative applications of old steel ropes in art installations or architecture showcase the potential for upcycling.